When particular factors this sort of as semiconductor devices, built-in circuits, and optoelectronic units are subjected to laser welding and packaging operations, the welding resources are uncovered to the air and are specifically inclined to oxidation under high temperature conditions, ensuing in welding problems such as porosity, slag inclusions, cracks, and minimal welding energy. , Top to soaring failure prices this sort of as bad airtightness, reduced power, and impact resistance of the unit, especially the influence resistance defect will lead to hurt to the unit flying high Mach, causing major basic safety mishaps and home losses. At existing, the domestic market urgently needs a The laser welding packaging system that can be utilized below vacuum circumstances or under particular atmosphere protection problems has a good man-machine environment and adaptable tools to satisfy the requirements of higher-conclude gadgets, especially specific gadgets for high-pace aerospace cars.

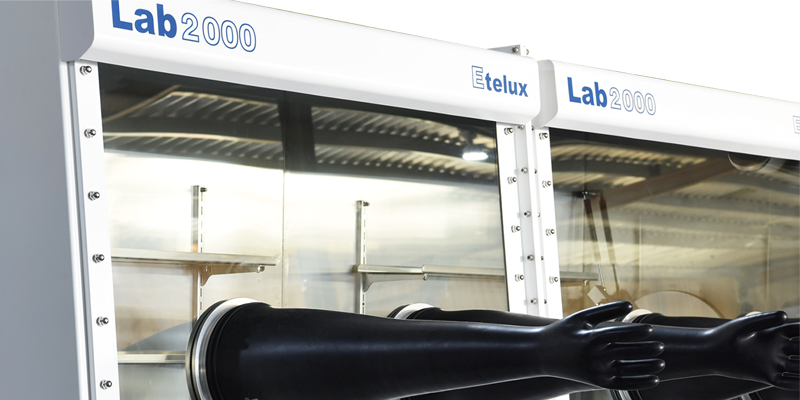

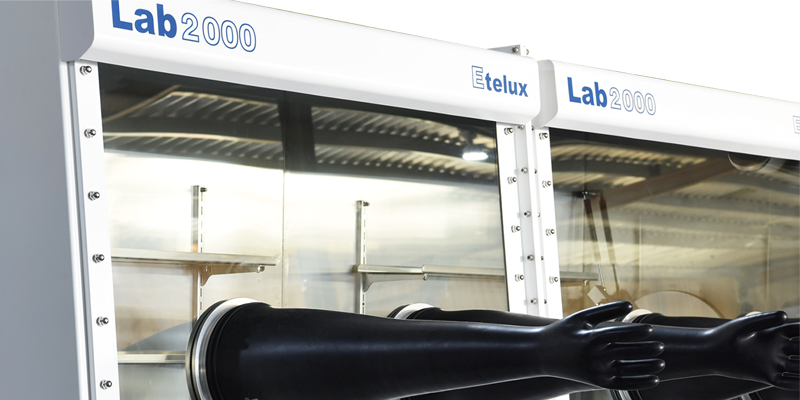

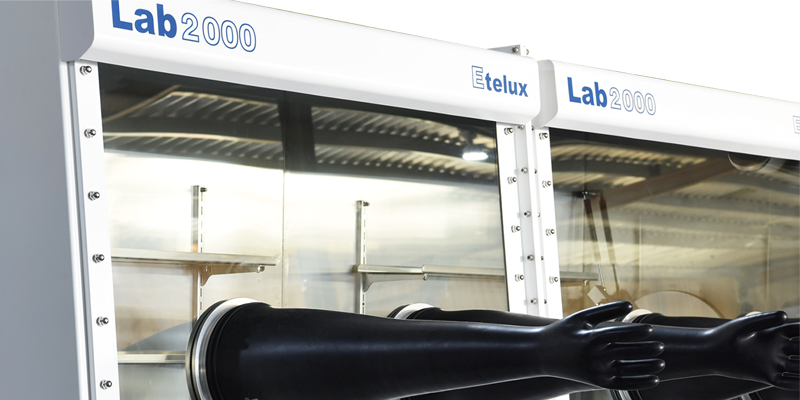

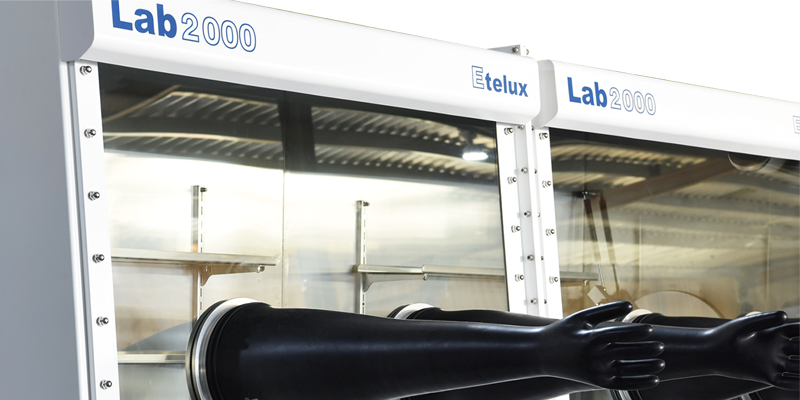

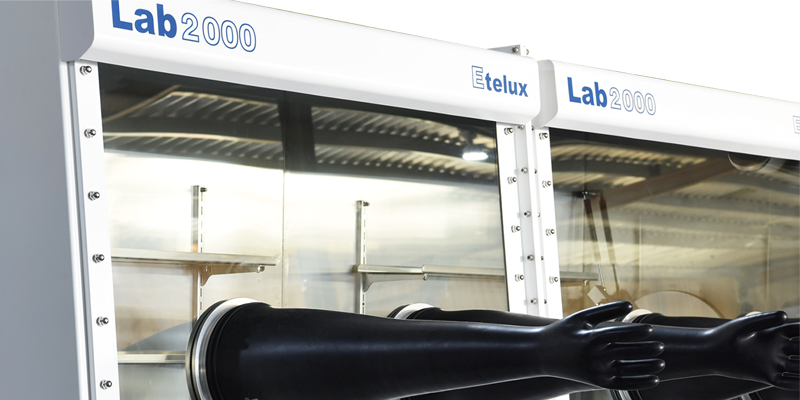

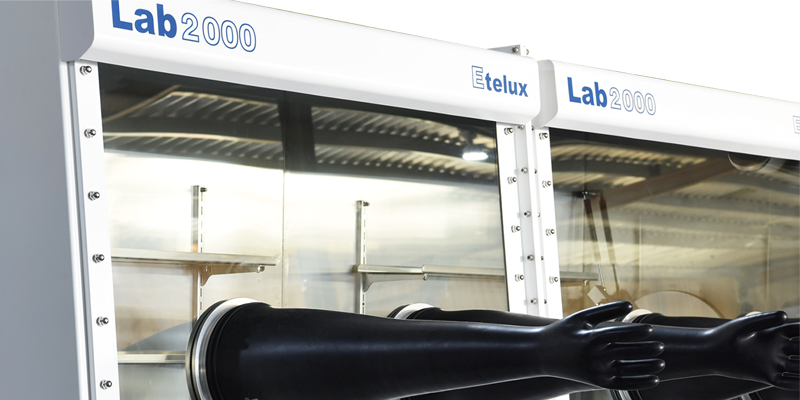

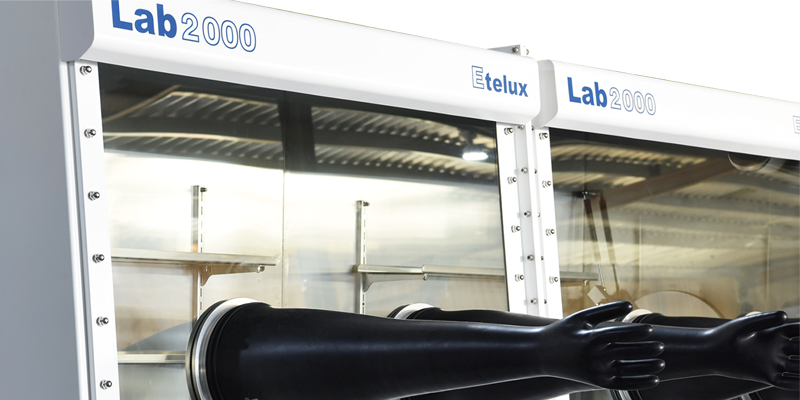

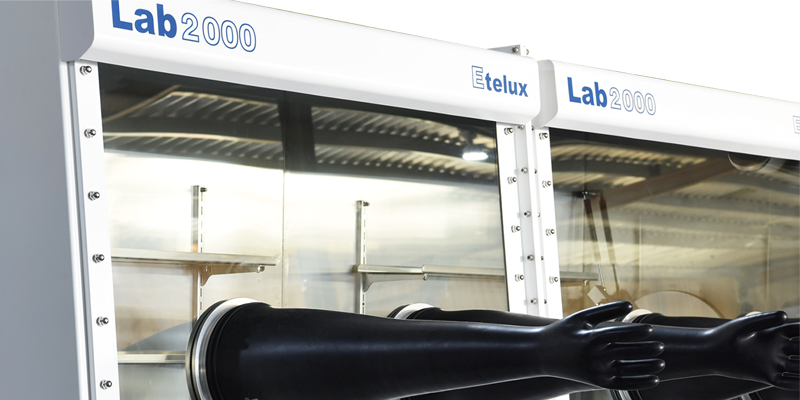

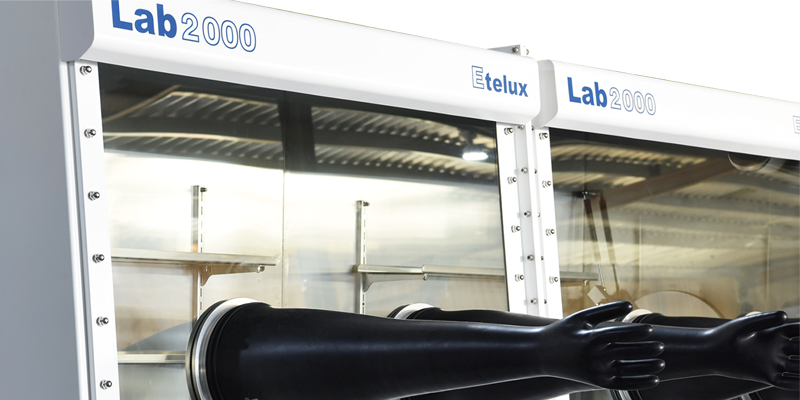

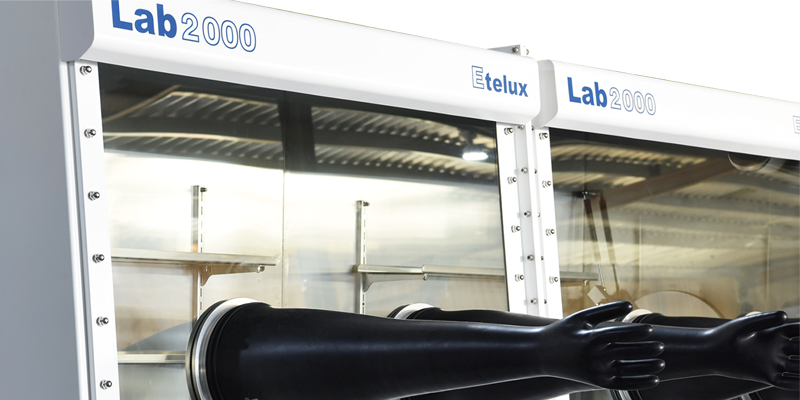

Etelux offers a laser welding glove box based on atmospheric protection. To fix the consequences of air humidity and air impurities in laser welding, the glove box has two ninety-diploma square cabins, the left aspect is the heating cabin, and the correct facet For the transitional cabin, the greatest temperature of the heating cabin is 200 ℃, the heating plate can be cooled speedily at the very same time, the outside of the sq. cabin doorway is a guide door, the internal doorway is an automated door, the internal and outer doorways are interlocked, the glove box is controlled to be cleaned by a circulation meter, and can also be linked to the purification system. laboratory glovebox are: lower leakage, lower water and oxygen content material in the box, stable total tools functionality, and accurate and reliable drinking water and oxygen detection.

How to adjust glove box gloves

Etelux glove box substitution of outdated and new gloves

1. Press the new gloves to be replaced into the box

2. Get rid of the outer O-ring, and then go the internal O-ring to the outer groove of the glove mouth

three. Roll the glove to the outdoors of the O-ring, getting treatment not to allow the glove fall from the mouth of the glove

4. Compress new gloves as considerably as possible to expel the air inside of

five. Set up the new glove on the glove mouth and place it on the previous glove

six. Set up an O-ring on the exterior of the new glove and the groove inside the glove mouth

7. If cheap glovebox , put the new gloves into the isolated working gasoline environment for cleaning (this can take away air and lessen the sum of air moving into the box)

eight. From within glovebox lab , use another glove to pull the previous glove into the box

nine. Set up an O-ring on the groove outdoors the glove exterior the new glove

ten. Get out the old gloves via the transition cabin and dispose of them properly.

Etelux Glove box laser welding packaging system

When glovebox lab of as semiconductor units, integrated circuits, and optoelectronic gadgets are subjected to laser welding and packaging operations, the welding components are exposed to the air and are notably susceptible to oxidation under high temperature problems, resulting in welding problems such as porosity, slag inclusions, cracks, and low welding strength. , Foremost to soaring failure costs these kinds of as bad airtightness, reduced toughness, and affect resistance of the system, specifically the effect resistance defect will trigger damage to the gadget flying higher Mach, creating significant basic safety accidents and residence losses. At existing, the domestic marketplace urgently requirements a The laser welding packaging device that can be used under vacuum circumstances or below specific atmosphere protection circumstances has a great guy-device setting and flexible equipment to meet the needs of large-end devices, specially particular products for substantial-speed aerospace automobiles.

Etelux gives a laser welding glove box based on atmospheric security. To solve the consequences of air humidity and air impurities in laser welding, the glove box has two 90-diploma square cabins, the remaining side is the heating cabin, and the proper facet For the transitional cabin, the highest temperature of the heating cabin is two hundred ℃, the heating plate can be cooled quickly at the very same time, the outside of the square cabin door is a manual doorway, the interior door is an computerized door, the interior and outer doorways are interlocked, the glove box is controlled to be cleaned by a flow meter, and can also be related to the purification system. Its characteristics are: minimal leakage, reduced drinking water and oxygen content in the box, stable all round equipment efficiency, and accurate and trustworthy drinking water and oxygen detection.

How to alter glove box gloves

laboratory glovebox of aged and new gloves

1. Thrust the new gloves to be replaced into the box

2. Remove the outer O-ring, and then transfer the interior O-ring to the outer groove of the glove mouth

three. Roll cheap glovebox to the outdoors of the O-ring, having treatment not to permit the glove slide from the mouth of the glove

four. Compress new gloves as much as feasible to expel the air inside

5. Put in the new glove on the glove mouth and place it on the aged glove

6. Set up an O-ring on the outdoors of the new glove and the groove within the glove mouth

seven. If achievable, place the new gloves into the isolated working gas environment for cleaning (this can get rid of air and lessen the sum of air moving into the box)

eight. From within the glove box, use one more glove to pull the aged glove into the box

nine. Install an O-ring on the groove exterior the glove outdoors the new glove

ten. Consider out the old gloves by way of the changeover cabin and dispose of them properly.

Safeguards when running the etelux glove box

Vacuum glove box is commonly utilised in industries with high specifications for fuel purification. Although the current glove box design is more affordable and effortless to operate. Nonetheless, glovebox accessories of the glove box is difficult, there are numerous critical elements, and the procedure is slightly incorrect, which could cause decline to your experimental final results. This report introduces you how to accurately use the vacuum glove box, and the safeguards when novices run the glove box.

One. Perform prior to operation:

one. Check out if there is glovebox gloves in the nitrogen bottle. The nitrogen must be replaced in time. The output strain of nitrogen is established to .4mpa.

two. Check whether or not the vacuum pump is turned on usually.

3. Verify regardless of whether the circulation in the glove box is open up. (Purification column-I or purification column-II must open up one of them)

4. Check out the upper restrict force in the setting ought to be +1, the decrease limit strain is

five. Examine whether or not oxygen and dew level are normal (oxygen is beneath .1ppm, dew stage is over -forty)

6. The vacuum pump of the more than-bin must be in the normally open up state

two. Procedure notes:

1. The vacuum pump should be kept on for the duration of program operation.

2. When the oxygen focus in the tank exceeds 200PPM, the gear upkeep staff should be notified to operate the program, or else the drinking water and oxygen purification technique will be destroyed.

3. Ahead of commencing the cycle, verify whether or not the cabinet is in problem or regenerating. As the earlier mentioned described operations are in progress, it is absolutely forbidden to cycle.

four .Two purification columns cannot be regenerated at the very same time.

A. Before regeneration, make sure that the glove box has been cleaned with inert gas (H2O <200ppm) to ensure sufficient supply of regeneration gas. The regeneration gas pressure is 0.06-0.08mpa.

B. Before starting regeneration, please make sure that the corresponding purification column circulation is closed.

C. The regeneration process takes 24 hours. Once the execution cannot be disconnected, the regeneration gas should be passed 3-6 hours after the regeneration starts. Pay attention to the amount of regeneration gas, adjust the pressure of the regeneration gas appropriately, and ensure the sufficient supply of regeneration gas in these 3 hours. After 6 hours the regeneration origin can be turned off.

D. The vacuum pump cannot be turned off during the regeneration process. Do not touch the top of the purification column to prevent burns.

E. Once the regeneration is terminated unexpectedly, please ensure that the regeneration and circulation of the purification column cannot be restarted within 12 hours or the equipment will be damaged.

5. Care should be taken to protect the work gloves from being damaged during the operation.

What must I pay out interest to when cleaning the dew position sensor in the glove box

Glove box water probe cleansing (only for washable probes)

one) Reason: If the water probe is not cleaned for a long time, some grime will adhere to the surface, affecting the detection.

2) Measures:

① Shut the cycle and analyzer

② Established the working strain to +five to + 8mbar

③Remove the water probe and swiftly blind the air outlet with a blind plate

④Unscrew the metallic protective cover on the front of the probe, wash it with deionized h2o, and then dry it with dust-totally free paper, then moisten the probe with dust-totally free paper dripped with cleansing fluid, and apply evenly

⑤ Place it back in spot, open the cycle, flip on the analyzer right after one hour, and return to normal degree after 50 % an hour.

observe:

Following Etelux Glovebox is cleaned, the glove box pressure is set to the authentic price, and the cycle is turned on but the analyzer is turned on yet again right after 1 hour, because soon after the water probe is cleaned, the probe surface area is cleaned with deionized water or 65% concentrated phosphoric acid wetting is made up of water Indeed, if the analyzer is turned on prematurely, the water value will always be detected and shown to exceed the common, so it is required to flow into in the tank for a whilst and wait around for the water vapor to dissipate ahead of turning it on again.

Software of glove box in lithium ion battery generation sector

1. Security issues in the procedure of lithium ion battery screening, manufacturing, transportation and use

Safety is to know whether the materials (pure matter) or its components (mixtures) are flammable, explosive, reactive, disease-causing, hugely poisonous, radioactive, corrosive, environmentally polluting, and so forth .

The transporter (may leak), the operator (might contact), the conclude item person (use basic safety), and of course environmental security.

two. Options to stability troubles

The remedy to the basic safety difficulty of lithium ion batteries is primarily in the test and production approach.

Because of to the really substantial oxidizability of lithium metal to h2o vapor and oxygen, the basic problems and gear specifications for the growth of lithium ion polymer batteries are extremely rigid, irrespective of earlier testing or assembly, they need to be in drinking water and oxygen concentration Carried out in extremely minimal atmosphere, these kinds of as glove box h2o, oxygen focus is less than 1PPM.

In the manufacturing approach of lithium batteries, water is the most significant enemy. cheap glovebox may decompose the electrolyte and have an effect on the overall performance of the battery. Drinking water will also respond with the constructive and adverse resources, so when filling the battery, it wants to be carried out in a glove box with a low humidity articles, and it can only be taken out of the glove box soon after filling and sealing.

three. lab glovebox — test products (functioning surroundings)

Etelux glove box is also referred to as tremendous clear glove box. The design and style overall performance of the glove box is to management the atmosphere to oxygen content material <1ppm and water content <1ppm. This process is achieved through an air purification system equipped with automatic valves and easy to install.

Application of glove box in lithium ion battery generation business

one. Protection difficulties in the approach of lithium ion battery tests, production, transportation and use

Safety is to know whether or not the content (pure matter) or its substances (mixtures) are flammable, explosive, reactive, illness-triggering, highly poisonous, radioactive, corrosive, environmentally polluting, and many others .

The transporter (may leak), the operator (may possibly contact), the end item user (use security), and of system environmental security.

two. laboratory glovebox to stability concerns

The resolution to the safety problem of lithium ion batteries is mostly in the take a look at and creation approach.

Due to the very higher oxidizability of lithium metallic to water vapor and oxygen, the fundamental problems and tools needs for the improvement of lithium ion polymer batteries are very rigorous, irrespective of preceding tests or assembly, they need to be in drinking water and oxygen focus Carried out in very low surroundings, these kinds of as glove box drinking water, oxygen concentration is considerably less than 1PPM.

In the producing method of lithium batteries, h2o is the largest enemy. Water could decompose the electrolyte and impact the functionality of the battery. Water will also react with the optimistic and adverse supplies, so when filling the battery, it wants to be carried out in a glove box with a reduced humidity articles, and it can only be taken out of the glove box soon after filling and sealing.

3. Related basic safety measures — test tools (functioning environment)

Etelux glove box is also named tremendous thoroughly clean glove box. laboratory glovebox of the glove box is to handle the setting to oxygen content <1ppm and water content <1ppm. This process is achieved through an air purification system equipped with automatic valves and easy to install.

Etelux Glove box regeneration methods

1) Regeneration gasoline: a combination of hydrogen and inert gas (hydrogen accounts for five% -10%)

two) Quantity: 40L gas cylinder 10Mpa

three) Regenerative gas stress: .05Mpa (the gas use for every 50 percent hour in the state of .05Mpa is that the cylinder stress drops by 1.5Mpa. If glovebox exceeds one.5Mpa, the strain of the force regulator’s schedule will be reduced, if it is significantly less than one.5Mpa Enhance the force of the stress regulator routine)

4) Method: 3 several hours heating-three several hours heating and air flow-3 hours vacuuming-1 hour pumping-ten hours cooling

five) Actions:

① Link the regeneration fuel (verify the pipeline for leaks right after link: soon after connecting, open the main valve of the strain minimizing valve to the optimum, open up the auxiliary meter to .1Mpa, turn off the principal valve, hold out 15 minutes, if the pressure of the auxiliary meter remains at .1 Mpa stays unchanged, indicating no air leakage)

②Set the force of the auxiliary gauge of the stress lowering valve to .1Mpa (the force in the course of ventilation is about .06-.08MPa)

③ Close the cycle and analyzer

④Turn on the vacuum pump

⑤ Begin regeneration

⑥ The new system finishes at 20h (clean prior to cleaning, water and oxygen index <200ppm).

6) Note: Do not cut off the power and gas during the regeneration process (especially the first 6 hours)! Some pressure reducing valves are not allowed, and the pressure needs to be adjusted appropriately to ensure continuous ventilation for 3 hours!

7) Observation: whether the regeneration gas flowmeter shows about 20L / min, otherwise adjust the pressure of the pressure reducing valve.

The resolution when the glove box encounters these faults

1. Massive and tiny warehouses can not replenish fuel

Factors: ① The air gap in the glove box foremost to the large and small warehouse could be blocked by plastic movie, etc . ② Whether or not the solenoid valve is not open up.

Technique: ① Decide the situation of the air gap and obvious the pipeline according to the pipeline path ② Check out the circuit and solenoid valve.

2. glovebox price and modest warehouses cannot be pumped

Causes: ① The suction holes in the large and modest bins are blocked by plastic film, and many others. or the door is leaking ② The bin doors are not shut tightly, or the seal ring of the massive and modest bins is loose.

Strategy: ① Establish the position of the air gap and distinct the pipeline in accordance to the course of the pipeline ② Close the warehouse door and verify the measurement of the sealing ring ③ Check out regardless of whether the functioning air strain is too lower (because the big warehouse exhaust valve is a pneumatic valve).

3. The box stress carries on to enhance during cleansing

Cause: The cleansing valve is not opened, the intake force is too substantial, and the pipeline is not smooth.

Methods: ①Ensure that the pipeline is easy, and it is ideal not to bend it ②When cleaning, the relative pressure in the tank is continually underneath .5 mbar.

four. The main valve of the purification column is faulty

Motives: ① The doing work gasoline stress is considerably less than .5Mpa ② The principal valve signal opinions failure.

Strategies: ①Replace the working gas cylinder, or examine the stress of the auxiliary gauge of the pressure reducing valve at .5Mpa

5. The cycle cannot be opened

Cause: Low-voltage or substantial-voltage defense of fan inverter.

Approach: Soon after the voltage is stable, shut down and restart right after 1 moment.